In the modern manufacturing landscape, efficiency is not a luxury—it's a necessity. Manufacturers face constant pressure to deliver high-quality products faster, at lower costs, and with fewer resources. Yet, outdated systems and manual workflows often get in the way. That's where Odoo ERP steps in.

Odoo ERP offers a comprehensive suite of tools specifically designed to streamline manufacturing processes. From production planning to inventory control, Odoo brings automation, visibility, and control to every corner of the shop floor.

This blog explores how businesses can streamline their manufacturing processes using Odoo ERP and why it has become a game-changer in the manufacturing sector.

Why Streamlining Manufacturing Processes Matters

Manufacturing involves multiple moving parts: procurement, production, quality control, inventory, and delivery. When these components operate in silos or rely on manual systems, inefficiencies arise. Common problems include:

- Inventory mismatches

- Delayed production

- Poor resource utilization

- Quality control failures

- Increased operational costs

Streamlining manufacturing processes helps eliminate these issues by ensuring smooth coordination across departments. It enhances productivity, reduces waste, and improves customer satisfaction.

Overview of Odoo Manufacturing Module

Odoo’s Manufacturing module is part of a larger, integrated ERP ecosystem. It's tailored for both small workshops and large-scale manufacturing units, offering features that allow businesses to plan, track, and control production efficiently.

Key highlights of the Odoo Manufacturing module:

- Integration with Inventory, Purchase, Sales, and Accounting modules

- User-friendly interface

- Real-time data visibility

- Custom workflows and automation

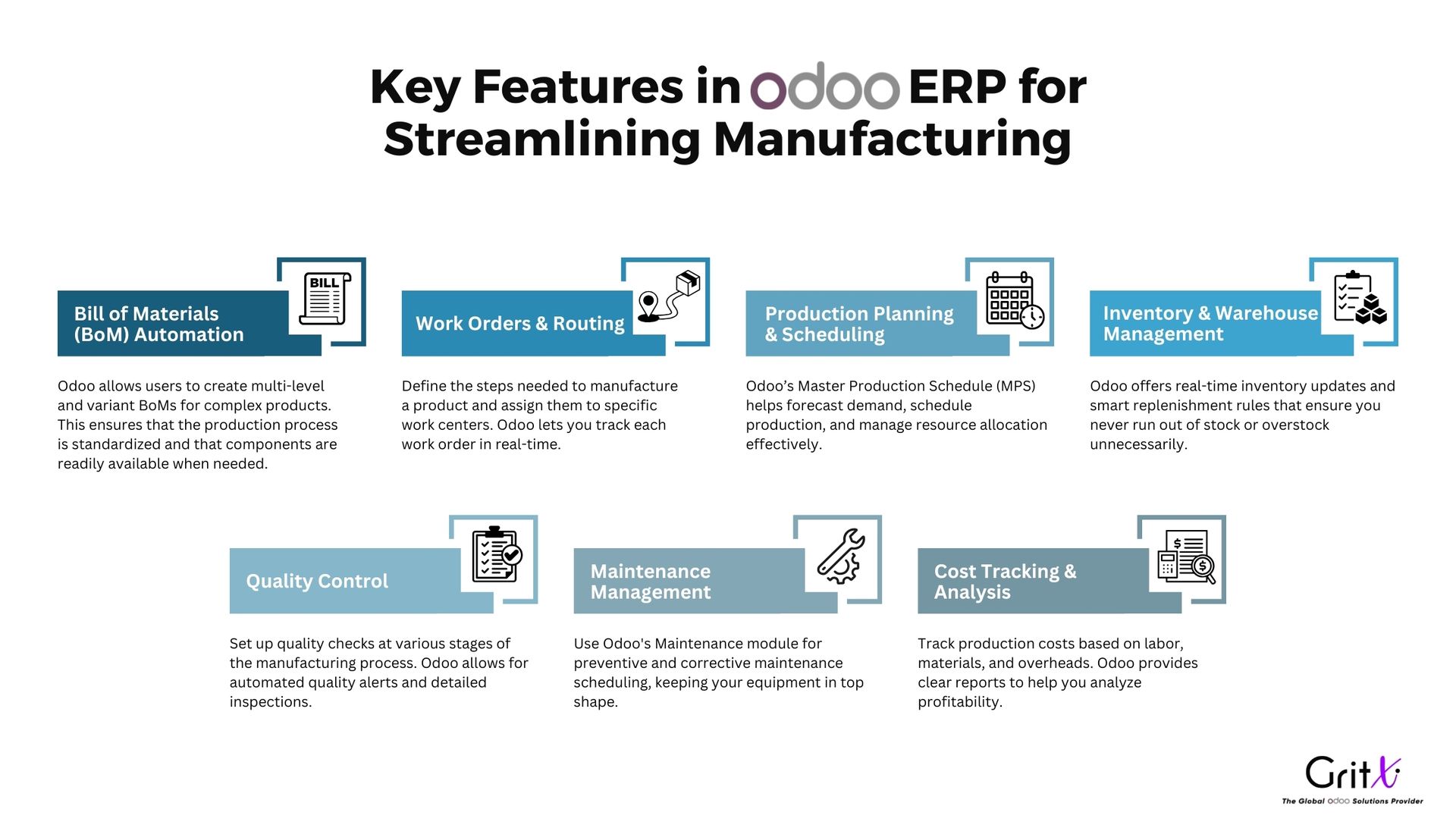

Key Features in Odoo ERP for Streamlining Manufacturing

1. Bill of Materials (BoM) Automation

Odoo allows users to create multi-level and variant BoMs for complex products. This ensures that the production process is standardized and that components are readily available when needed.

Benefits:

- Reduced manual errors

- Better inventory forecasting

- Improved production planning

2. Work Orders & Routing

Define the steps needed to manufacture a product and assign them to specific work centers. Odoo lets you track each work order in real-time.

Benefits:

- Real-time progress updates

- Minimized bottlenecks

- Improved task management

3. Production Planning & Scheduling

Odoo’s Master Production Schedule (MPS) helps forecast demand, schedule production, and manage resource allocation effectively.

Benefits:

- Optimized production cycles

- On-time delivery

- Better demand planning

4. Inventory & Warehouse Management

Odoo offers real-time inventory updates and smart replenishment rules that ensure you never run out of stock or overstock unnecessarily.

Benefits:

- Accurate stock levels

- Reduced holding costs

- Efficient warehouse operations

5. Quality Control

Set up quality checks at various stages of the manufacturing process. Odoo allows for automated quality alerts and detailed inspections.

Benefits:

- Consistent product quality

- Fewer returns and complaints

- Regulatory compliance

6. Maintenance Management

Use Odoo's Maintenance module for preventive and corrective maintenance scheduling, keeping your equipment in top shape.

Benefits:

- Reduced downtime

- Prolonged equipment life

- Fewer unexpected breakdowns

7. Cost Tracking & Analysis

Track production costs based on labor, materials, and overheads. Odoo provides clear reports to help you analyze profitability.

Benefits:

- Better budgeting

- Transparent cost structure

- Improved pricing strategies

Real-Time Visibility and Reporting

With Odoo, manufacturers gain access to custom dashboards that display key performance indicators (KPIs) such as:

- Production output

- Machine efficiency

- Inventory turnover

- Lead times

These insights empower decision-makers to identify issues early and take corrective action quickly.

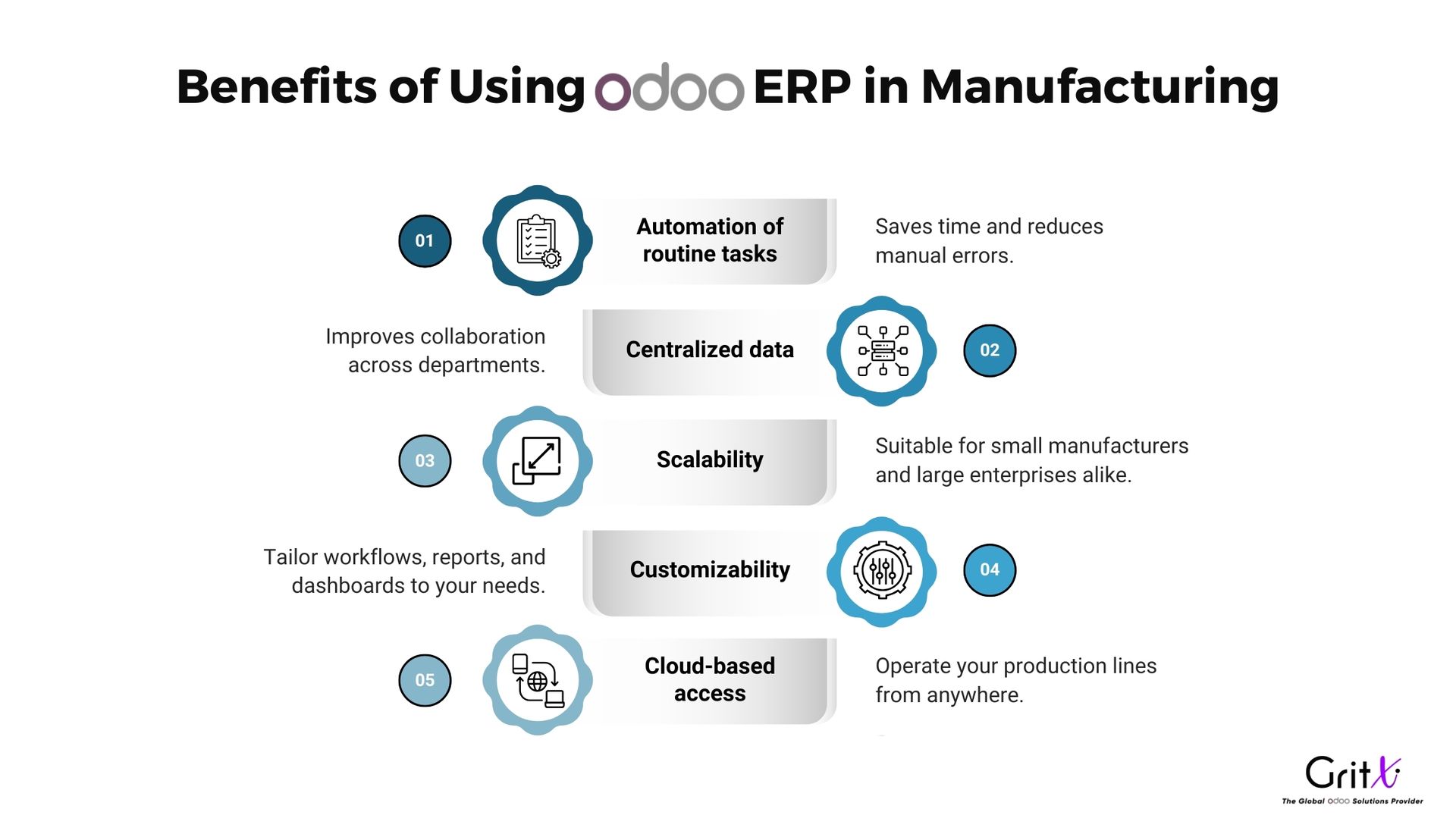

Benefits of Using Odoo ERP in Manufacturing

- Automation of routine tasks: Saves time and reduces manual errors.

- Centralized data: Improves collaboration across departments.

- Scalability: Suitable for small manufacturers and large enterprises alike.

- Customizability: Tailor workflows, reports, and dashboards to your needs.

- Cloud-based access: Operate your production lines from anywhere.

How to Implement Odoo ERP in Your Manufacturing Business

Step 1: Process Evaluation Identify inefficiencies and define clear goals.

Step 2: Choose the Right Odoo Partner Work with certified Odoo experts to ensure proper implementation.

Step 3: Configuration & Customization Set up modules based on your specific workflow.

Step 4: Data Migration Transfer existing data like product details, inventory, and vendor lists.

Step 5: Training & Testing Train your staff and test the system thoroughly.

Step 6: Go Live & Monitor Launch the system and monitor its performance regularly.

Final Thoughts

Streamlining your manufacturing operations is crucial for staying competitive in today’s market. Odoo ERP offers an all-in-one solution that empowers manufacturers to automate, optimize, and grow.

Whether you're struggling with disconnected systems or simply looking to scale efficiently, Odoo Manufacturing is your pathway to smarter, leaner production.

Ready to transform your manufacturing operations? Get in touch with an Odoo expert and schedule your free demo today.

FAQs

Q1. Is Odoo suitable for small manufacturing businesses?

Yes. Odoo is scalable and works well for both SMEs and large enterprises.

Q2. Can I customize Odoo's manufacturing workflows?

Absolutely. Odoo is highly customizable to suit your business processes.

Q3. How long does it take to implement Odoo ERP?

Depending on the complexity, implementation can take from a few weeks to a few months.

Q4. Does Odoo support multi-level Bill of Materials (BoM)?

Yes. Odoo supports complex, multi-level BoMs and product variants.

Q5. What other modules can integrate with Odoo Manufacturing?

Inventory, Purchase, Sales, Accounting, Maintenance, and Quality Control modules all integrate seamlessly.

How to Streamline Manufacturing Processes with Odoo ERP: A Complete Guide